Το καλάθι σας

Το καλάθι σας είναι άδειο

Ειδήσεις Για Την Εταιρεία Μας

Τα Μπαχαρικά μας

Η ζάχαρή μας

Τα Καπάκια μας

-

Crown Caps 26 mm TFS-PVC Free, Red col. 2941 (10000/box)

Προσθέστε

Crown Caps 26 mm TFS-PVC Free, Red col. 2941 (10000/box)

Προσθέστε

-

Kegcaps 64 mm, Red 150 Sankey S-type (EU) (1000/box)

Προσθέστε

Kegcaps 64 mm, Red 150 Sankey S-type (EU) (1000/box)

Προσθέστε

-

Kegcaps 69 mm, Green 147 Grundey G-type (850/box)

Προσθέστε

Kegcaps 69 mm, Green 147 Grundey G-type (850/box)

Προσθέστε

-

ΚΑΠΑΚΙΑ 26mm TFS-PVC Free, Green Transparent col. 2722 (10000/box)

Προσθέστε

ΚΑΠΑΚΙΑ 26mm TFS-PVC Free, Green Transparent col. 2722 (10000/box)

Προσθέστε

-

Kegcaps 64 mm, Blue 141 Sankey S-type (EU) (1000/box)

Προσθέστε

Kegcaps 64 mm, Blue 141 Sankey S-type (EU) (1000/box)

Προσθέστε

Γλωσσάριο

A tall glass (traditionally 3 feet) that was originally produced in England back in the days when travel by horse-drawn coach was common. When a coach would stop at an Inn to rest the horses and feed the passangers, the Coach driver would have to stay on the coach to handle the reigns. Since the coach driver wanted beer, but was way up there on the coach while the barmaids where way down there on the ground, the yard glass was developed to help the barmaids hand the beer up to the coach driver. A yard glass typically has a large mouth, a long skinny neck, and a large bulb at the bottom. It takes a bit of practice, but it certainly is an entertaining and traditional way to enjoy beer.

Yeast collected from fermentors during or after the fermentation.

A brewing additive which is typically produced by extracting the "guts" of yeast cells in a centrifuge. Provides essential nutrients to the yeast. Since barley malt already contains all of the nutrients that yeast need, yeast engergizer is generally unnecessary when brewing beer. It may be more helpful in wines, ciders and meads (fruit juices and honey do not contain the level of nutrients that barley does).

A brewing additive which adds free amino nitrogen (FAN), a substance which is essential for good yeast health. Think of it as fertilizer for your yeast. As with yeast engergizer, should not be necessary for beer wort, since malt already contains all of the essential nutrients for your yeast.

Essentially a small, mini-batch of beer, the sole purpose of which is to give your yeast culture a contaminant-free environment in which it can build up their strength and numbers. For detailed info on how I make yeast starters.

Number of pounds of extract, obtained from 100 pounds of brewing material, given in percent. Also kilos extract per kilo brewing material. Distinguish between laboratory yield of malt and adjunct which is determined by standard ASBC methods and brewhouse yield, which depends on equipment and operating conditions. Brewhouse yield ranges from 92 to 98% of laboratory yields.

English system of fermentation using shallow, square, traditionally slate vessels for fermentation. Still in use by the Samuel Smith Brewery in Tadcaster, Yorkshire.

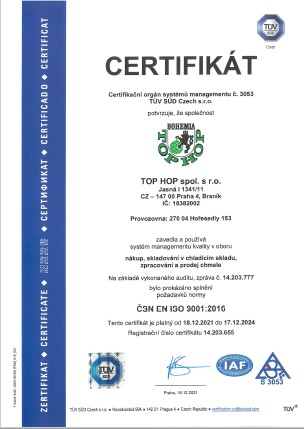

Top Hop - ISO Certificate 2021-2024

Top Hop - ISO Certificate 2021-2024

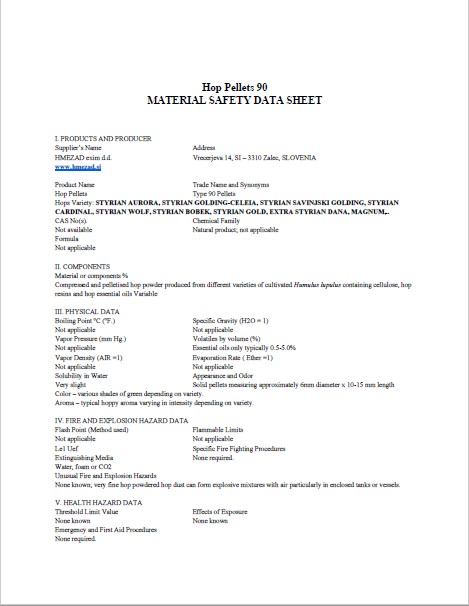

HMEZAD Hops - Material Safety data sheet 2022

HMEZAD Hops - Material Safety data sheet 2022

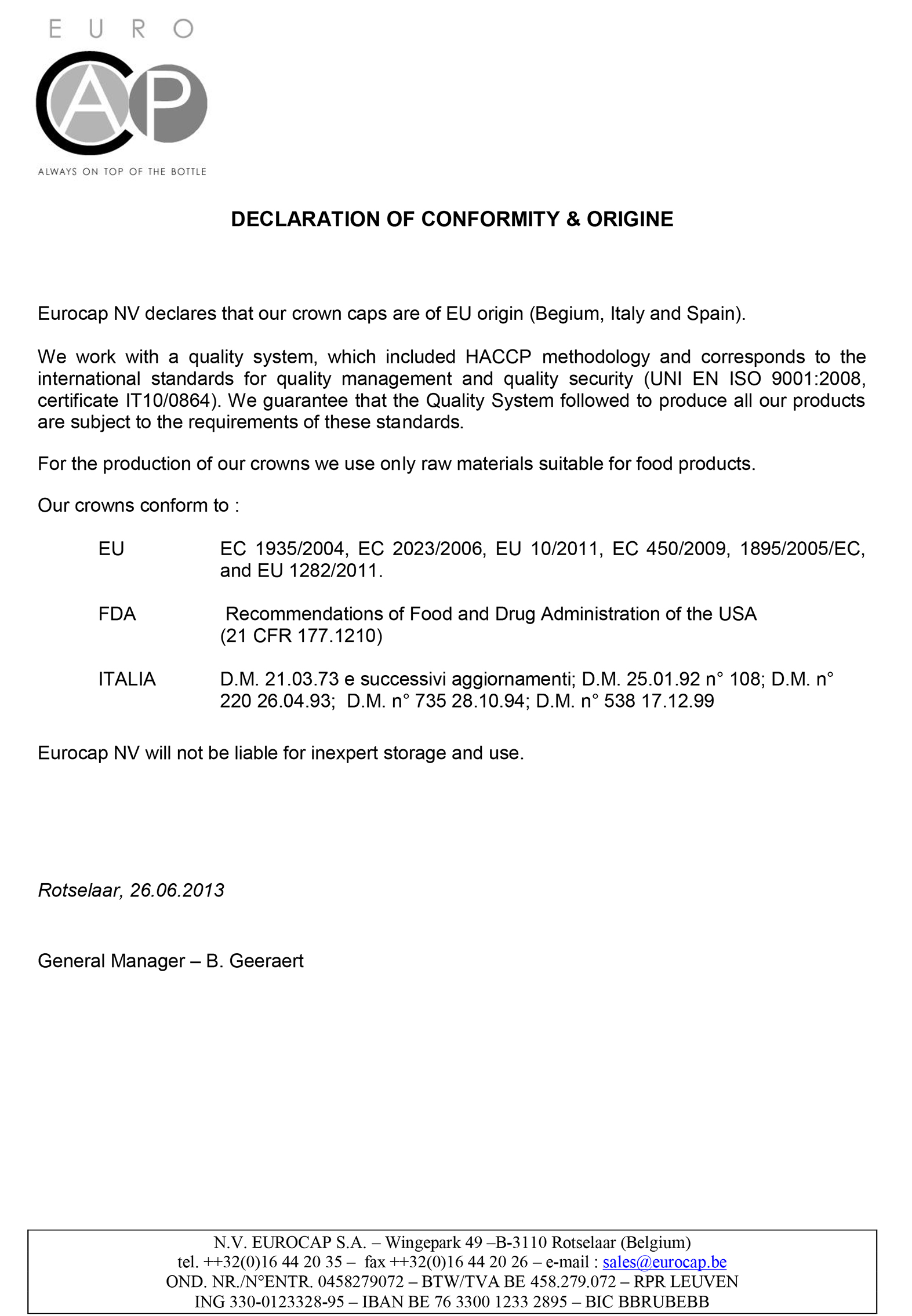

Crown Caps EUROCAP Conformity and Origin Certificate

Crown Caps EUROCAP Conformity and Origin Certificate

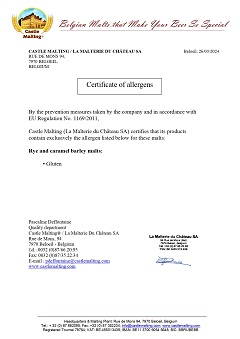

Malt Allergen Certificate for Rye and Caramel Barley Malt (ENG)

Malt Allergen Certificate for Rye and Caramel Barley Malt (ENG)

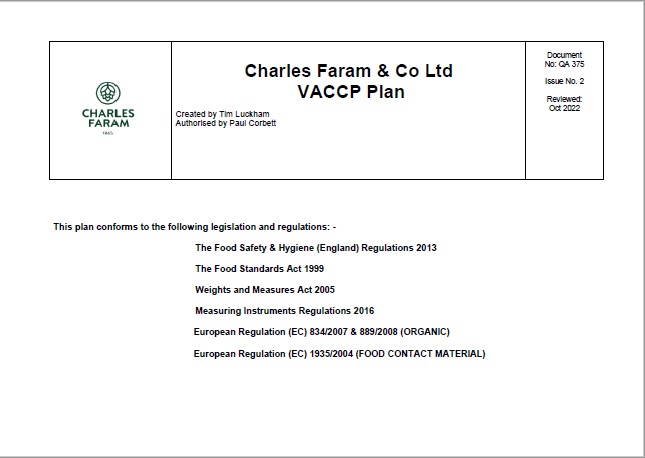

Charles Faram Hops, VACCP Plan QA375, EN 2022

Charles Faram Hops, VACCP Plan QA375, EN 2022