Twój koszyk

Twój koszyk jest pusty

Aktualności firmowe

Nasze przyprawy

Nasze cukry

Nasze kapsle

-

Kapsle 26mm TFS-PVC Free, Gold Neu Matt col. 2981 (10000/box)

Dodaj do koszyka

Kapsle 26mm TFS-PVC Free, Gold Neu Matt col. 2981 (10000/box)

Dodaj do koszyka

-

Kegcaps 64 mm, Brown 153 Sankey S-type (EU) (1000/box)

Dodaj do koszyka

Kegcaps 64 mm, Brown 153 Sankey S-type (EU) (1000/box)

Dodaj do koszyka

-

Kegcaps 74 mm, White 86 Flatfitting A-type (700/box)

Dodaj do koszyka

Kegcaps 74 mm, White 86 Flatfitting A-type (700/box)

Dodaj do koszyka

-

Kegcaps 74 mm, Zielony 147 Flatfitting A-type (700/box)

Dodaj do koszyka

Kegcaps 74 mm, Zielony 147 Flatfitting A-type (700/box)

Dodaj do koszyka

-

Kapsle 26mm TFS-PVC Free, Mustard yellow col. 20164 (10000/box)

Dodaj do koszyka

Kapsle 26mm TFS-PVC Free, Mustard yellow col. 20164 (10000/box)

Dodaj do koszyka

Słowniczek

A type of hexose sugar occurring in small quantities in beer, fermented very slowly by yeast.

Liquid volume measure: One U.S. gallon = 3.785 liters, One British gallon = 4.546 liters

A device used to mix gases together to push the beer from the keg without over or under pressurizing the beer in the keg. Beer industry standards specify blending CO2 and Nitrogen together. Recommended blenders are preset at the factory and require no adjustments. Gas Blenders are recommended for high volume accounts, as well as, accounts where temperature fluctuations are common, and there is a need for a high amount of pressure to push the beer from the keg to the faucet.

Used to connect the primary regulator to the secondary regulator, the blender, or the CO2 inlet of the keg coupler. Gas line is available in a variety of materials such as vinyl or braided vinyl, with a selection of colors and sizes. Red is usually used for lines with less than 50 lbs of pressure. Braided line is used for systems that require more than 50 lbs of applied pressure.

Ordinary, unflavored gelatin may be used as a clarifying agent, by dissolving a teaspoon of unflavored gelatin in some water, and adding to the fermenter after fermentation is complete. The gelatin binds with yeast cells, and helps them to settle out.

The process of rendering starches soluble in water by heat, or by a combination of heat and enzyme action, is called gelatinization.

The embryo of a cereal grain.

Beginning of vegetation or growth in seeds.

An important protein group present in barley and in beer. It is the prime component in chill haze.

An enzyme that act on beta glucans, a type of gum found in the endosperm of unmalted barley, oatmeal, and wheat.

Glucose "loving" usually used in referring an organism that thrives on glucose, such as yeast.

The most basic unit of sugar. A single sugar molecule.

Goblets can resemble a fishbowl. Typically they have a round bowl and come in various sizes. They are somewhat like a brandy or cognac snifter. Use these for high alcohol sipping beers.

A strong Belgian style of ale, of which Duvel is the best-known example.

A fine mesh bag, usually made of nylon or cotton. Typically used by extract brewers, to steep specialty grains in the brewing water.

The grain bed is formed by the collection of grist particles and grain husks on top of the false bottom of the lauter/mash tun. Once established the grain bed allows for the separation of the clear wort from the spent grains during sparging.

This is the term used to refer to the total amount and types of grains used in a particular beer recipe. One of my favorite beers has a "grain bill" consisting of 7 lbs 2-Row, 1 lb Malted Wheat, and 1 lb rice.

The combination of all grains that will be used for a particular batch of beer. Prepared prior to milling and mashing.

A device designed to crush malt and grain, for brewing. The best mills for brewing are roller mills, which crush the grain between parallel rollers. Plate mills, which crush the grain between textured metal plates, are designed to make flour, not brewing grist; they can be used for brewing, but must be carefully adjusted, or the grist will be either to fine, or too coarse.

Sugar products derived from grain, intended for use as adjunct equivalents for extract-based beers.

A smaller open-topped vessel placed between the lauter tun and boiling kettle, through which the wort is run during the sparge. It allows the brewer easy access to the wort which is being run off, such that it can be monitored both visually and with various brewing tools such as a thermometer, hydrometer, and pH meter. Most homebrewers do not employ a grant. The grant also allows for a buffer zone between a pump and the lauter tun. If the pump were pulling directly on the lauter-tun, it could compact the grain bed and lead to a stuck sparge. But if the beer is allowed to gravity-flow into the grant, and then the pump sucks on the grant, this problem is avoided.

A characteristic of wort. It is measured in percents or degrees of Balling. The latter is a percentage of a mass of extracted substances (in grams) dissolved in a hundred grams of water. Named after 19th century Czech chemist Karl Napoleon Balling.

A term often used synonymously with "crush".

A dry mixture (flour like powder) of ground malts and adjuncts used in mashing.

1) Ground degermed corn or rice used in brewing.

2) Processed grain that has undergone husk, bran and germ removal. Grits are generally ungelatinized.

2) Processed grain that has undergone husk, bran and germ removal. Grits are generally ungelatinized.

Glass jug, typically 1/2 gallon capacity. Commonly used by brewpubs and micro breweries in the US, to sell fresh draft beer for carry-out.

A medieval herb mixture used in beer.

The spontaneous and sometimes vigorous overfoaming of bottled beer when a non-shaken bottle is opened.

The wort before the yeast is pitched.

Calcium sulphate (CaSO4). Very common in water. Often used as a water additive to correct water chemistry or duplicate the water of a particular region. It also can be used to acidify the mash and inhibit the deactivation of alpha-amylase by high temperatures.

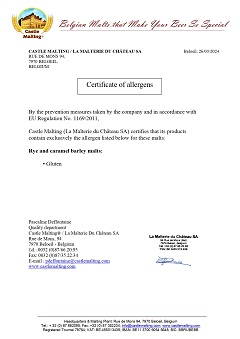

Malt Allergen Certificate for Rye and Caramel Barley Malt (ENG)

Malt Allergen Certificate for Rye and Caramel Barley Malt (ENG)

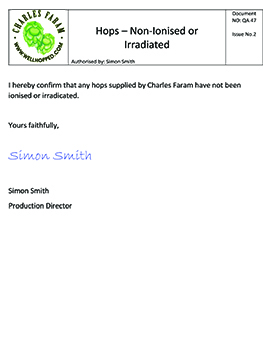

ChF Hops Non-Ionization and Non-Irradiation Certificate

ChF Hops Non-Ionization and Non-Irradiation Certificate

Bio-Zertifikat DE - Juli 2025-März 2028

Bio-Zertifikat DE - Juli 2025-März 2028

Belgosuc Sugar, GMO-Free Certificate 2019

Belgosuc Sugar, GMO-Free Certificate 2019

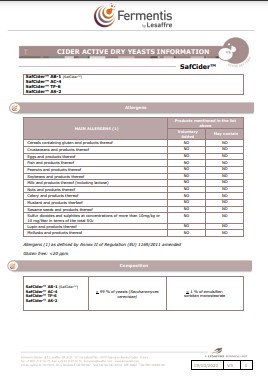

Fermentis - Cider Dry Yeast Information 2023

Fermentis - Cider Dry Yeast Information 2023